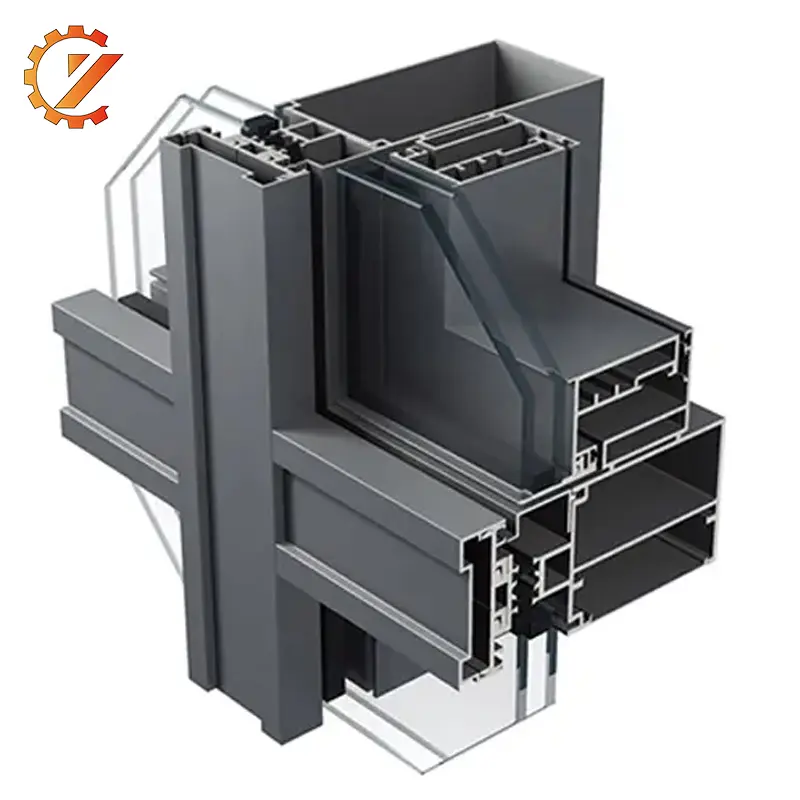

Aluminum Curtain Wall Profile for Glass Wall Building

Product Introduction

Key Advantages (Bullet Points)

Outstanding Structural Stability and Load-bearing Capacity:

Glass curtain wall aluminum profiles offer high strength and rigidity, stably supporting large glass panels and making them suitable for curtain wall systems in super-high-rise buildings.

Excellent Weather Resistance and Durability:

The aluminum profiles are treated with processes such as anodizing and fluorocarbon spraying, creating a uniformly thick protective layer that resists harsh outdoor environments such as UV rays, acid rain, and high temperature fluctuations. They are resistant to rust, fading, or deformation over long-term use, resulting in a service life of decades and reduced curtain wall maintenance costs.

Strong Design Flexibility and Adaptability to Architectural Aesthetics:

Thermal Insulation and Energy Saving Performance Compliant with Green Building Standards: Aluminum profiles employing thermal insulation technology effectively block heat conduction, reducing energy consumption for air conditioning and heating in buildings.

Significant advantages in lightweighting and construction efficiency: The density of aluminum profiles is only 1/3 that of steel, significantly reducing the overall weight of the curtain wall and the load-bearing load of the main building structure.

TO KNOW MORE ABOUT, PLEASE CONTACT US!

- jasonjiao813@gmail.com

-

Linqu County, Weifang City, Shandong Province

Our experts will solve them in no time.