-

Home

-

About Us

-

Products

-

Customer Cases

-

Service

-

News

-

Blog

-

Contact Us

Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

When planning a construction project, selecting the right materials is crucial. One important choice is the Aluminum Guardrail. This system is essential for ensuring safety in various environments, from commercial buildings to outdoor spaces. According to industry reports, the use of guardrails can reduce fall-related injuries by up to 50%.

Aluminum Guardrails are lightweight and resistant to corrosion. They are ideal for areas exposed to harsh weather. However, not all Aluminum Guardrails are created equal. It's vital to consider factors like design, height, and installation requirements. Some options may not fit specific needs as anticipated. It’s advisable to prioritize quality over cost.

In the end, the right Aluminum Guardrail doesn't just protect; it enhances the overall project. This selection can impact aesthetics and functionality. Don't overlook the importance of making informed choices. A little research can lead to better decisions that safeguard both people and investments.

When selecting aluminum guardrails, understanding specifications and standards is crucial. A report by the American Association of State Highway and Transportation Officials (AASHTO) highlights that guardrails must meet certain safety standards. These include impact resistance and durability factors that ensure a long lifespan. Remember, not all aluminum is created equal. The alloy type can significantly influence its strength.

Consider the dimensions specified by the International Building Code (IBC). It recommends railings to be at least 42 inches in height and withstand a minimum load of 200 pounds. Many projects overlook these details. A guardrail that meets the height requirement might still fail under pressure if the installation is flawed. The connection points around the rail must be secure. Inadequate anchoring can lead to catastrophic failures.

Another vital aspect involves local weather conditions. Aluminum guardrails perform well in various climates, but exposure to saltwater can corrode certain alloys. Some studies indicate that 30% of coastal constructions report premature deterioration. This statistic underscores the importance of choosing appropriate materials for specific environments. Failing to do so may complicate long-term maintenance and safety concerns.

When selecting aluminum guardrails for any project, the material and finish are crucial. According to industry reports, around 30% of guardrail failures occur due to inadequate corrosion resistance. Choosing a higher-quality aluminum alloy can prevent this. Alloys like 6061 or 6063 are popular choices. They offer good strength and corrosion resistance. You should consider the environment the guardrail will be exposed to. For coastal locations, additional coatings may be necessary to combat saltwater corrosion.

The finish of the aluminum also matters. Anodized and powder-coated surfaces provide different levels of protection. Anodizing can enhance corrosion resistance but may not provide the same color variety as powder coating. Reports show that powder-coated finishes offer better UV resistance, which is essential in sunny areas. Yet, they may chip or scratch more easily, leading to potential maintenance issues over time.

While aesthetics are important, they shouldn’t overshadow functionality. A visually appealing guardrail must still meet safety standards. Some projects overlook this balance, leading to costly revisions. Regular maintenance checks can help identify early signs of wear. This approach can reduce long-term costs and improve safety outcomes. It’s imperative to weigh both looks and durability in your decision-making process.

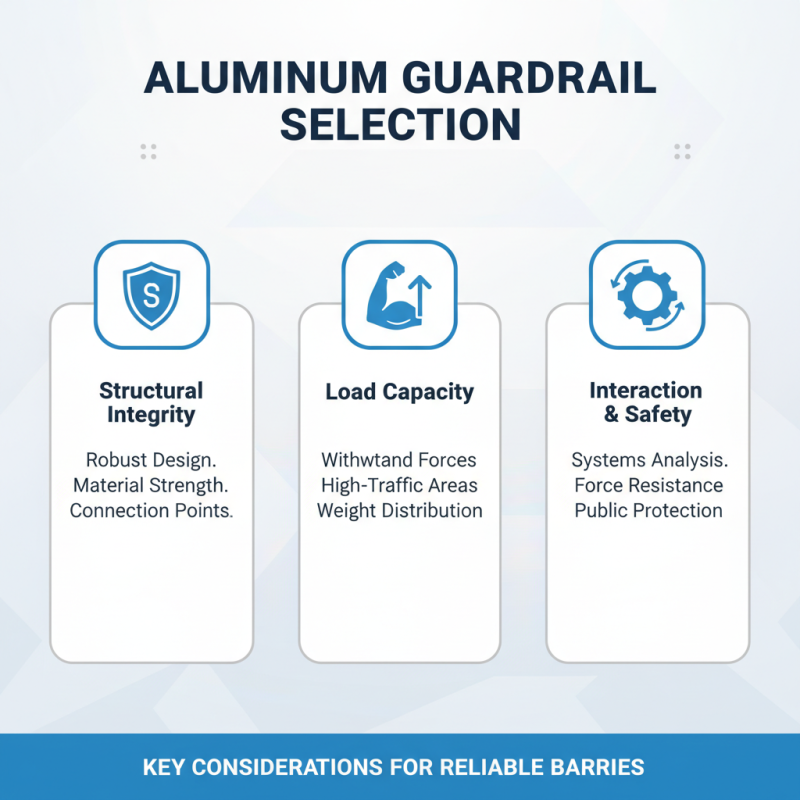

When choosing aluminum guardrails, one must consider structural integrity and load capacity carefully. The guardrail should withstand various forces, especially in high-traffic areas. Understanding how these elements interact is crucial.

Evaluate the material's thickness and design. Thicker materials can typically handle more weight and pressure. Look for guardrails with strong welds and connections. These features help prevent failure in challenging conditions. Testing should be done to ensure performance meets safety standards.

Visual inspections are important. Notice any signs of wear or defects. Regular maintenance checks can uncover issues before they become serious. Consulting with engineers can provide insights, but sometimes, product information may lack depth. This can lead to uncertainty in decision-making. Remember, a well-chosen guardrail not only adds safety but can also enhance the overall aesthetic of a project.

When budgeting for aluminum guardrail installation, it’s crucial to consider various factors. The average cost of aluminum guardrail systems can range from $15 to $30 per linear foot. Installation costs typically add another $10 to $20 per linear foot. Unexpected expenses often arise during projects, such as site preparation and compliance with local regulations. It's essential to build a buffer into your budget for these potential additional costs.

A recent industry report highlighted that about 30% of project managers exceed their initial budgets due to unforeseen issues. Proper planning can help mitigate these risks. Consider engaging with professionals early in the design phase. This collaboration often leads to more accurate estimations, minimizing budget overruns. Analyzing your overall project costs should also include maintenance expenses. Aluminum guardrails generally require less maintenance than other materials, which can offer long-term savings.

Quality and safety must remain priorities. In some cases, opting for cheaper materials might lead to higher liabilities or replacements in the future. Additionally, work with a contractor who understands the intricacies of guardrail systems. This partnership can prevent costly mistakes. Reflect on your choices and their impact on both costs and safety outcomes as you finalize your decisions.

| Guardrail Type | Height (ft) | Material Thickness (mm) | Cost per Linear Foot ($) | Installation Cost per Foot ($) | Total Estimated Cost for 100 ft ($) |

|---|---|---|---|---|---|

| Standard Aluminum | 4 | 2 | 25 | 15 | 4000 |

| Heavy-Duty Aluminum | 5 | 3 | 30 | 20 | 5000 |

| Architectural Aluminum | 6 | 4 | 35 | 25 | 6000 |

| Lightweight Aluminum | 3 | 1.5 | 20 | 10 | 3000 |

Maintaining aluminum guardrail systems is crucial for ensuring their longevity. Regular inspections should be part of your maintenance routine. Look for signs of wear, corrosion, or damage. These issues can compromise safety and durability. It’s easy to overlook minor scratches or chips, but they can lead to bigger problems over time.

Cleaning is another essential practice. Use mild soap and water to remove dirt and grime. Avoid harsh chemicals that might harm the finish. Rinse thoroughly to prevent residue build-up. Occasionally, applying a sealant can enhance protection against the elements. However, not all sealants are suitable for every aluminum type.

Consider seasonal changes. In winter, ice and snow can accumulate. This additional weight may stress the guardrails. Ensure snow is cleared promptly to avoid damage. During extreme weather, inspect the guardrails more frequently. Sometimes, you may miss critical issues during regular checks, so make these inspections thorough. Each detail matters in preserving the safety and aesthetics of your guardrail system.