-

Home

-

About Us

-

Products

-

Customer Cases

-

Service

-

News

-

Blog

-

Contact Us

Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

When it comes to choosing and using Aluminium Pipe Bends effectively, insights from industry expert John Smith can be invaluable. He states, “The right bend can enhance the flow and efficiency in any piping system.” This highlights the importance of selecting appropriate Aluminium Pipe Bends for various applications.

Aluminium Pipe Bends are essential components in many industries, from construction to manufacturing. Their lightweight and durable nature makes them a preferred choice. Yet, the selection process can be confusing. Many overlook crucial factors like bend radius and end connection types. This oversight can lead to inefficiencies and costly repairs down the line.

Understanding the specific requirements for your project is key. Take time to assess the environment in which the pipe will operate. Consider pressure, temperature, and fluid type. Remember, not all Aluminium Pipe Bends are created equal, and a lack of careful planning can lead to significant issues. Make informed choices to ensure optimal performance.

Aluminium pipe bends are essential in various applications, such as plumbing, HVAC systems, and automotive engineering. These components allow for directional changes in piping systems while minimizing resistance to flow. According to a recent industry report, the global aluminium pipe market is expected to grow significantly, projected to reach $145 billion by 2025. This growth reflects the increasing demand for lightweight materials in industries focused on fuel efficiency and sustainability.

Understanding the specific applications of aluminium pipe bends is crucial. They are often used in tight spaces where standard piping cannot fit. For example, in HVAC systems, proper bends can enhance airflow and reduce energy consumption. However, some designs may create unnecessary pressure drops, which requires careful consideration. Engineers often face challenges balancing aesthetics with functionality in their designs, leading to possible inefficiencies.

One common oversight is not calculating the bend radius correctly. If the radius is too tight, it may lead to failure over time. In industries where physical stress is a concern, this can cause leaks or even catastrophic failures. While aluminium pipe bends offer numerous advantages, it's vital to analyze their use case thoroughly. Only with the right approach can the maximum potential of these components be realized.

| Dimension | Bend Angle | Material Thickness (mm) | Applications |

|---|---|---|---|

| 20 mm | 90° | 1.5 | HVAC systems |

| 25 mm | 45° | 2.0 | Plumbing |

| 32 mm | 180° | 2.5 | Industrial equipment |

| 40 mm | 60° | 3.0 | Framework construction |

| 50 mm | 30° | 3.5 | Furnace construction |

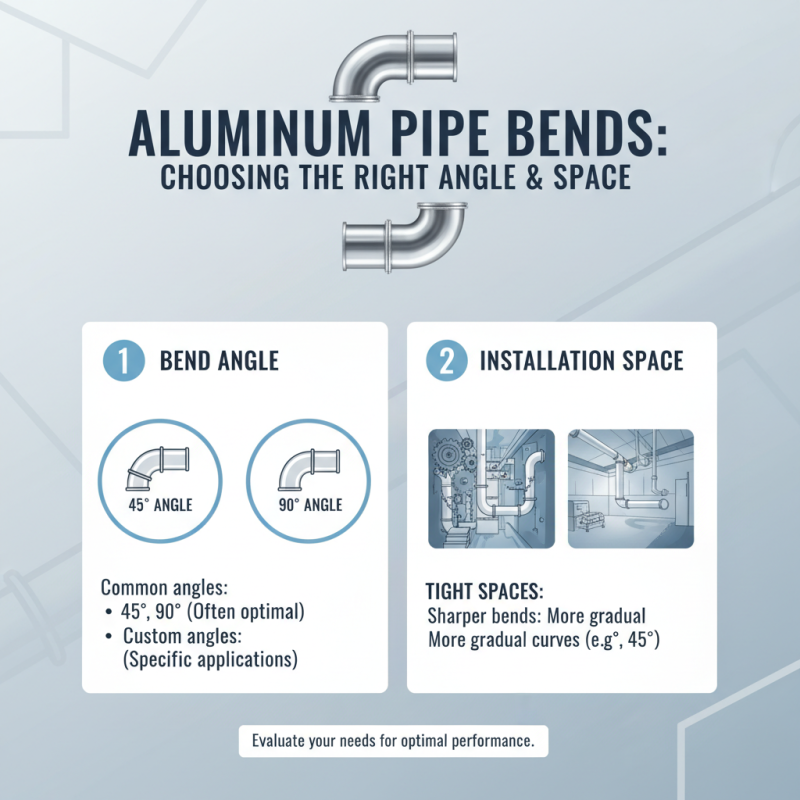

When choosing aluminium pipe bends, several critical factors come into play. Firstly, consider the angle of the bend. Common angles, like 45 and 90 degrees, often work best. However, custom angles may be needed for specific applications. Evaluate the space where the pipe will be installed. Tight spaces may require a sharper bend, while open areas can accommodate more gradual curves.

Next, the diameter of the pipe is essential. A mismatch between the bend and the pipe size can lead to flow issues. The thickness of the aluminium also matters. Thicker pipes tend to withstand greater pressure. However, they are also heavier and may require more robust supports.

Material quality should not be overlooked. Though aluminium is generally durable, variances exist. Some bends may corrode faster than others, especially in harsh environments. Regular inspections are essential to identify wear and tear over time. These considerations are vital for ensuring efficiency and longevity in your piping system.

Choosing the right aluminium pipe bends is crucial for various applications. There are several types available in the market. The most common ones are 45-degree and 90-degree bends. Each type serves specific purposes in plumbing and construction. A 90-degree bend, for example, is typically used when a sharp turn is needed in a pipeline system.

Research shows that aluminium bends can handle high pressure and temperatures. They are lightweight, yet strong, making them an excellent choice for many projects. According to industry data, the global aluminium pipe market is expected to grow by over 4% annually. However, users often underestimate the importance of selecting the correct bend type. A mismatch can lead to leaks or failures. Users should consider materials, dimensions, and compatibility with existing pipes.

Numerous options also include welded and seamless bends. Welded bends are often stronger but may have surface imperfections. Seamless bends offer a smoother finish but can be costly. It's essential to weigh the pros and cons of each type. Sometimes, a cheap option can lead to higher long-term costs. Hence, careful thought in the selection process matters significantly.

When installing aluminium pipe bends, attention to detail is crucial. Ensure you measure accurately before cutting the pipes. Proper measurements can prevent costly mistakes later. Use a saw suitable for aluminium to achieve clean cuts. A messy cut can lead to poor fitting and leaks.

After cutting, deburr the edges. Sharp edges can damage seals and compromise joints. Use a file or deburring tool to smooth the edges. This step can seem minor but should not be overlooked. Ensuring a smooth surface helps in achieving tight, secure connections.

When assembling the bends, utilize appropriate fittings. Always double-check alignment before securing. Misaligned connections can lead to stress on the pipe bends during operation. This stress could result in failures over time. Some may rush this step, thinking they can fix it later. In reality, revisiting poorly fitted pipes can be tedious.

Maintaining aluminium pipe bends is crucial for ensuring their durability. A few simple maintenance practices can significantly extend their lifespan. Regular inspections should focus on identifying any signs of wear or corrosion. If you notice discoloration or pitting, prompt action is needed. A quick cleaning with a mild detergent and water can remove dirt and help prevent long-term damage.

It’s vital to ensure the bends are installed correctly. Improper installation can lead to stress points. Over time, these can result in leaks or failures. Using the right tools during installation is also a key factor. Avoid using excessive force. This can compromise the integrity of the bend. Checking for tight connections and proper alignment should be routine.

Additionally, consider environmental factors. Extreme temperatures and exposure to certain chemicals can affect aluminium. If your application involves harsh conditions, protective coatings may be necessary. However, applying these coatings isn’t always perfect; sometimes they wear down faster than expected. A scheduled maintenance plan is essential, even when everything seems fine. Regular checks, adjustments, and cleaning can save you time and money later on.