-

Home

-

About Us

-

Products

-

Customer Cases

-

Service

-

News

-

Blog

-

Contact Us

Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

Choosing the right Aluminum Rod for your project can be daunting. There are many factors to consider. Different applications require different rod specifications. The type of alloy, rod diameter, and length can affect your project's outcome.

When selecting an Aluminum Rod, think about strength and weight. Some projects need lightweight materials. Others prioritize durability. Knowing your project's goals helps narrow down your options. For example, if you need corrosion resistance, certain alloys may be better. Consider how the aluminum will be used, too.

Don't overlook the importance of precision. A slight error in rod specifications can lead to project delays. Reflect on what works best for your needs. Sometimes trial and error is part of the process. This journey to find the right Aluminum Rod requires careful thought and sometimes, unexpected insights.

When selecting an aluminum rod, it's vital to understand the types available.

Aluminum rods come in various alloys, each designed for specific uses.

For instance, 6061 is a popular choice for its excellent strength and weldability. It's often used in structural applications.

In contrast, 2024 offers higher strength and is favored in aerospace. However, it can be harder to weld.

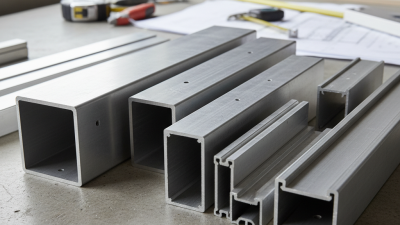

Consider the rod's diameter and length too.

Many projects require specific measurements to ensure a proper fit.

Standard diameters range from 1/8 inch to several inches. Additionally, length may vary based on your needs.

Pay attention to these details; you don’t want to waste material by cutting and discarding the wrong size.

Surface treatment is another factor.

Some rods are raw, while others are anodized for better corrosion resistance.

Each option has its pros and cons.

Raw rods are typically cheaper, but they might require more maintenance over time.

Anodized rods offer longer-lasting durability but at a higher cost.

You may question which is best for your project.

Testing different types might help you make better decisions.

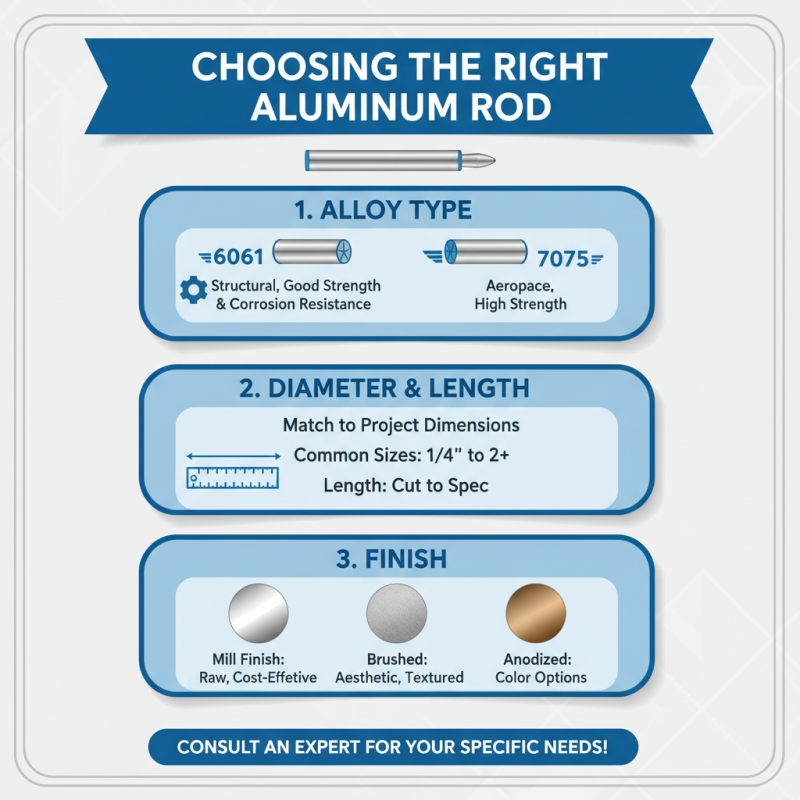

Choosing the right aluminum rod for your project is crucial. You need to consider several key factors. The first factor is the alloy type. Different alloys offer varying properties like strength and corrosion resistance. For example, 6061 is commonly used for structural applications due to its good mechanical properties.

Next, think about the diameter and length of the rod. These dimensions will affect the strength and weight of your final product. A thicker rod can handle more load, but it will also add weight. You might end up with too much weight if you don’t plan carefully. Ensure that the specifications match your project’s needs.

Don’t forget about the surface finish. Some projects require a smooth, polished surface. Others may benefit from a rough texture for enhanced grip. It's worth noting that the finish can impact both aesthetics and functionality. Depending on your experience, choosing the right finish could be tricky. Ask for samples if you're unsure. Each detail can significantly affect your project’s success.

When selecting aluminum rods, assessing strength and durability is essential. Different projects require different properties. For instance, the tensile strength of 6061 aluminum is about 310 MPa, making it a popular choice for structural applications. This strength allows it to withstand significant loads. However, not all projects demand the same levels of strength.

Consider the environment where the aluminum rod will be used. Aluminum can corrode, especially in harsh settings. An industry report from the Aluminum Association notes that corrosion resistance can decrease durability significantly. For example, a rod exposed to marine environments may need protective coatings. This need can complicate choices, adding extra costs and steps to the project.

Additionally, reflect on your specific application requirements. Even with high strength ratings, the rod's performance can vary based on shape and finish. A report from ASTM International emphasizes that uneven surfaces can lead to stress concentrations. These might lead to unexpected failures. Take the time to evaluate these factors carefully, as overlooking them can impact project success.

When evaluating the cost-effectiveness of aluminum rods, several factors come into play. Different grades and sizes can affect price significantly. For instance, a standard 6061 aluminum rod may cost less upfront, but it offers less strength compared to a 7075 grade. This discrepancy can influence long-term performance and durability. Selecting a cheaper option might appear smart initially, but hidden costs can arise from frequent replacements or repairs.

Another aspect to consider is the weight-to-strength ratio of aluminum rods. Some projects require lightweight materials without sacrificing strength. Aluminum rods that are higher in quality typically provide better performance, leading to potential savings down the line. Compare the lifespan of various options. A rod that lasts longer reduces overall expenses. Think about the specific requirements of your project. Sometimes investing a little more yields greater benefits.

Also, consider local suppliers and shipping costs. Sometimes, a cheaper rod may come with higher shipping fees, negating savings. The best choice requires careful calculation. Evaluate not just the price tag but the long-term value and expected returns. Reflecting on the true cost can reveal important insights.

Choosing the right aluminum rod for your project requires careful consideration. Begin by identifying the specific requirements of your application. Aluminum rods vary in size, alloy, and finish. Ensure to measure dimensions precisely. The right dimensions affect strength and usability.

When sourcing aluminum rods, request samples if possible. This helps in assessing the material’s quality. Examine surface finish, as it impacts durability. Not all suppliers provide consistent quality. Therefore, research their reputation before making a decision.

Discuss your needs with potential suppliers. Explain the intended use and load requirements. This communication can lead to better guidance. Don’t hesitate to ask questions. Understanding the alloy types can be challenging. Each one has unique properties. Being informed leads to smarter choices. Reflect on past purchases. Were they ideal for your projects? Learning from experience can guide future decisions.

This chart illustrates the importance of different criteria when selecting aluminum rods for various projects. The criteria include Strength, Weight, Corrosion Resistance, Cost, and Availability, providing insights into what factors may influence purchasing decisions.