-

Home

-

About Us

-

Products

-

Customer Cases

-

Service

-

News

-

Blog

-

Contact Us

Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

Choosing the right Aluminum Round Tube can significantly impact your project. Whether it’s for construction, automotive, or DIY needs, selecting the correct tube is crucial. This decision can affect strength, weight, and durability.

Aluminum Round Tubes come in various sizes and grades. Each type serves different purposes. For instance, some tubes are lightweight, making them ideal for portable applications. Others provide greater strength, suitable for structural support. Understanding your project’s requirements is vital.

Many users overlook the importance of proper sizing and material choice. A common mistake is choosing a tube that does not match the load requirements. This can lead to unexpected failures. Reflecting on these factors will ensure your project runs smoothly and efficiently.

Aluminum round tubes are versatile materials found in various applications. They are commonly used in construction, automotive, and aerospace industries. Their lightweight nature makes them easy to handle, while their strength ensures durability. Often, these tubes can be seen in scaffolding, furniture, and structural components. Understanding their properties helps in selecting the right type for each project.

Choosing the right aluminum round tube can be challenging. You need to consider factors like diameter, wall thickness, and alloy composition. Each detail has a role in the tube's performance. For instance, a thicker wall provides more strength but increases weight. Conversely, a thinner wall reduces weight but may not support heavy loads. Reflecting on these choices is crucial. Are you prioritizing strength over weight? Or do you need a balance of both?

In some cases, selecting the wrong tube can lead to project setbacks. Inspect your design requirements closely. If you overlook specific needs, it may result in inadequate support or functionality. This highlights the importance of thoughtful selection. Evaluating your project’s demands ensures the right choice, leading to better outcomes.

When selecting an aluminum round tube, understanding key specifications is essential. Diameter plays a crucial role in determining the tube’s overall strength and weight. A larger diameter can offer greater load-bearing capacity. However, this also adds to the material costs. For projects requiring high strength with minimal weight, a balance is key. Consider the specific application to select the right size.

Wall thickness is another important factor. Thicker walls provide more durability, making the tube resistant to bending and crushing. However, this can lead to an increase in weight, which may not be suitable for all projects. For some applications, such as lightweight structures, a thinner wall may suffice. It's essential to assess the operational environment.

Length also matters significantly. Standard lengths are available, but custom lengths can be required. Cutting the tube to the desired length can lead to inconsistencies. Be mindful of measurements before finalizing your choice. Each specification influences the overall performance of the tube. A thoughtful evaluation can prevent costly mistakes in your project.

Choosing the right aluminum round tube can greatly affect your project's success. Among the common alloy grades, 6061 and 6063 stand out. Both are popular, but they have distinct properties that might suit different needs.

6061 is known for its superior strength. It's often used in structural applications. This alloy can handle heavy loads and stresses. However, its strength comes with a slight downside. It may not be as aesthetically pleasing as 6063. That can matter if visual appeal is part of your project. On the other hand, 6063 has excellent extrudability. It's often chosen for architectural applications, thanks to its smooth finish. However, its lower strength can be a concern for some users.

When deciding between the two, consider your project's needs. If strength is the priority, 6061 might be the better choice. But if you desire a sleek appearance with good corrosion resistance, consider 6063. It’s a balancing act. Each material has trade-offs that could impact your project’s outcome.

Budgeting for aluminum round tubes can be tricky. It’s essential to assess your project needs thoroughly. Consider the type of project you are working on. Will it bear heavy loads? Or is it for decorative purposes? Knowing the use will guide your material choices.

Next, evaluate the available budget. Prices of aluminum tubes vary widely. Thickness, diameter, and length play a huge role in costing. Sometimes, a cheaper option may not provide the necessary strength. This can lead to future expenses on repairs.

Also, think about long-term usage. Will this project last? If not, investing in high-quality materials seems unnecessary. Additionally, consider sourcing your tubes. Local suppliers may charge more but can save shipping costs. Weighing these factors helps make a smarter choice. It's all about finding that balance between quality and budget.

| Tube Diameter (inches) | Wall Thickness (inches) | Length (feet) | Weight (lbs) | Cost per Unit ($) |

|---|---|---|---|---|

| 1.0 | 0.065 | 12 | 2.2 | $10.50 |

| 1.5 | 0.065 | 12 | 3.2 | $12.00 |

| 2.0 | 0.083 | 12 | 4.6 | $15.75 |

| 2.5 | 0.120 | 12 | 5.9 | $18.40 |

| 3.0 | 0.120 | 12 | 7.4 | $22.00 |

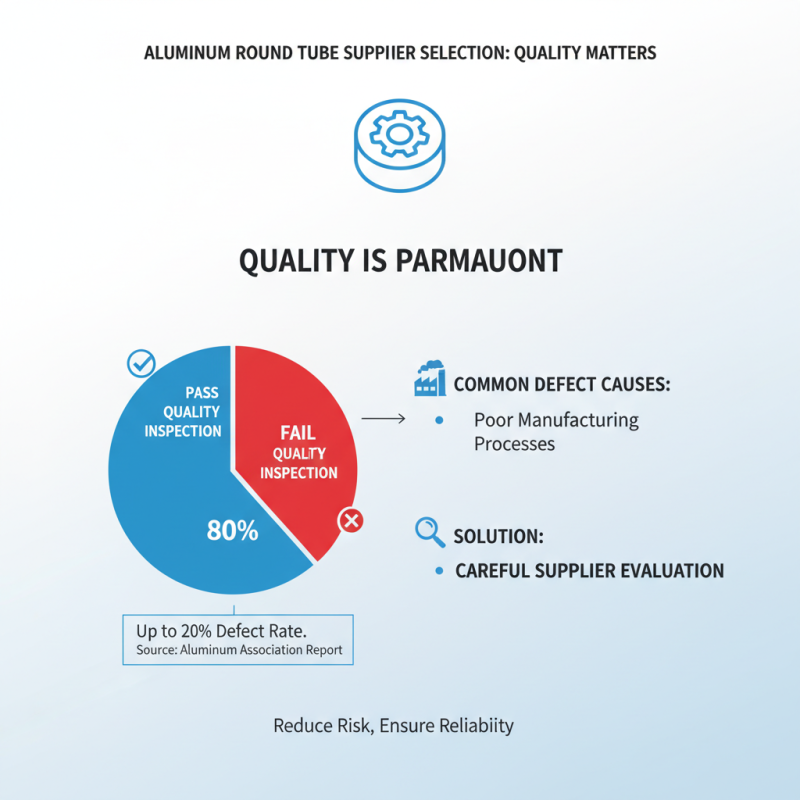

When selecting suppliers for aluminum round tubes, quality is paramount. A comprehensive report from the Aluminum Association indicates that defects can arise from poor manufacturing processes. Up to 20% of aluminum products may fail quality inspections. This statistic emphasizes the need for careful supplier evaluation.

Inspect the supplier's certifications. ISO 9001 and ASTM standards are vital indicators of quality assurance. A recent market analysis shows that suppliers with these certifications have a 30% lower failure rate in product quality. Certifications reflect a supplier's commitment to maintaining standards and improving processes.

Consider the supplier's track record and customer reviews. Reliable suppliers often have a history of meeting deadlines and fulfilling orders. A study by the Metallurgical Society revealed that 55% of procurement professionals prioritize supplier reliability over price. While cost is important, the long-term impact of choosing a dependable supplier can save time and resources.