-

Home

-

About Us

-

Products

-

Customer Cases

-

Service

-

News

-

Blog

-

Contact Us

Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

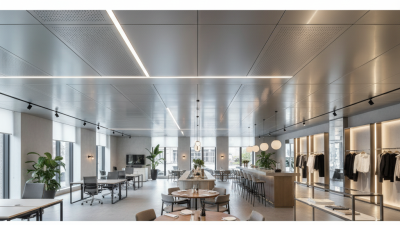

Choosing the right Aluminium Plate for your project can be challenging. According to industry expert Mark Johnson, "Selecting the right material is crucial for project success." His insight highlights the importance of informed choices.

Aluminium Plates come in various sizes, thicknesses, and grades. Each option impacts performance and durability. For instance, a plate too thin might warp under pressure, while a heavier one could add unnecessary weight. It's essential to assess your project's specific requirements.

In many cases, beginners may overlook critical factors like alloy composition or surface treatment. These elements can affect the plate's strength and corrosion resistance. Taking time to understand these details can prevent future complications. Ultimately, the right Aluminium Plate can elevate the quality of your work.

When selecting the right aluminium plate for any project, it's crucial to understand the various types available. Aluminium plates typically fall into several categories. These include 6061, 5052, and 7075 alloys, each with unique properties. The 6061 alloy is recognized for its good mechanical properties and corrosion resistance, making it a commonly chosen option for structural applications. According to the Aluminium Association, this alloy accounts for nearly 30% of total aluminium use in construction.

The 5052 plate is notable for its excellent workability and weldability. It's often used in marine and automotive applications. Interestingly, while this type offers great resistance to saltwater corrosion, it’s essential to consider environmental factors. Reports indicate that exposure to harsh conditions can lead to performance issues over time. On the other hand, 7075 alloy is favored for its high strength but can be more challenging to machine.

Choosing the right type of aluminium plate requires reflection on both performance and long-term durability. A project’s specific requirements should guide the decision. Not all options are perfect; for example, some may struggle with severe weather conditions. Thus, understanding the context in which these plates will be used can significantly influence their performance.

| Tip | Description | Common Uses | Thickness Range |

|---|---|---|---|

| 1. Determine Material Type | Choose between 1000, 2000, 3000, 4000, 5000, 6000 series based on properties. | Structural, automotive, marine applications. | 1mm - 100mm |

| 2. Assess Strength Requirements | Know the required tensile strength and yield strength for the project. | Aerospace, military applications. | 2mm - 150mm |

| 3. Identify Finish Type | Select between mill finish, anodized, or painted based on aesthetics and durability. | Architectural, consumer goods. | 1mm - 20mm |

| 4. Check Corrosion Resistance | Evaluate environmental factors that may influence corrosion levels. | Marine, chemical processing. | 3mm - 25mm |

| 5. Evaluate Weight Constraints | Consider weight allowances and limitations in your project. | Transport, aerospace. | 2mm - 50mm |

| 6. Review Fabrication Options | Identify feasible fabrication methods based on the type of aluminium plate. | Custom projects, build components. | 5mm - 30mm |

| 7. Investigate Cost Factors | Analyze cost implications related to thickness, quality, and finish. | Budgeting for projects. | 1mm - 100mm |

| 8. Ensure Compliance with Standards | Confirm that materials meet industry standards and regulations. | Construction, manufacturing. | 3mm - 60mm |

| 9. Factor in Thermal and Electrical Conductivity | Assess the importance of conductivity based on application. | Electronics, heat exchangers. | 1mm - 40mm |

| 10. Consult with Experts | Seek advice from professionals to ensure optimal material selections. | Professional engineering, high-stakes projects. | 2mm - 100mm |

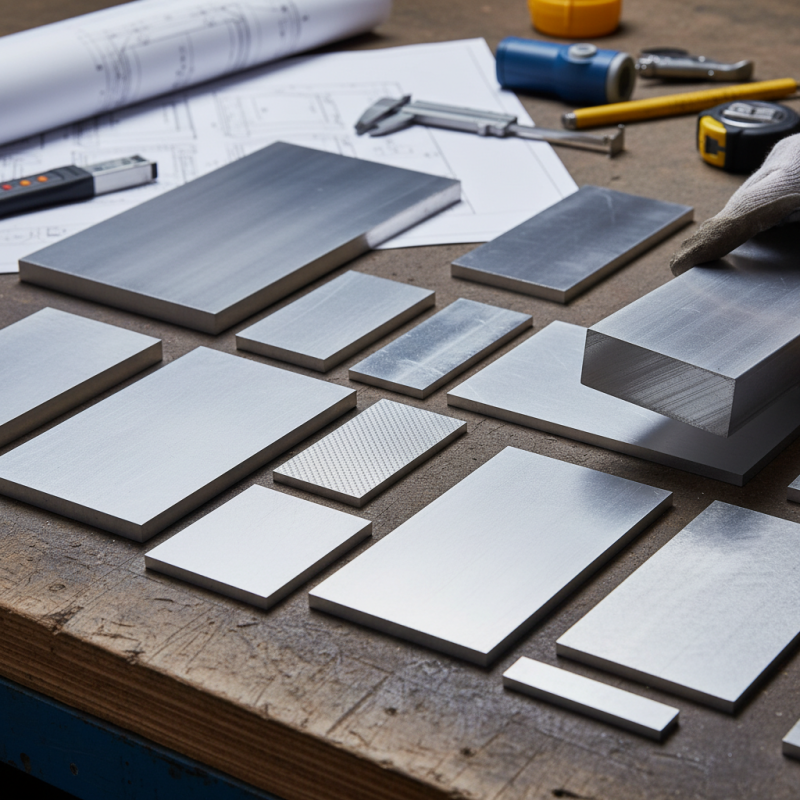

When choosing an aluminium plate, thickness and dimensions play a vital role. The required thickness often depends on the project's demands. For example, structural applications may need thicker plates for enhanced durability. A 1-inch plate can withstand heavy loads, while a 0.25-inch plate might suffice for lighter applications. Balancing these specifications is crucial to meet both strength and weight criteria.

Dimensions also significantly affect the project's feasibility. A plate that is too large can complicate handling and installation. Conversely, a small plate may not cover the necessary area. It’s essential to measure the space carefully. Consider the margins for cutting and shaping. Unforeseen issues can arise if dimensions are not precise.

It's common to overlook these factors. Many jump into purchasing without proper evaluation. Understanding the specific requirements ensures that you choose the right aluminium plate. Measure twice, cut once is a valuable lesson here. Think ahead about how the material fits into your overall design and functionality.

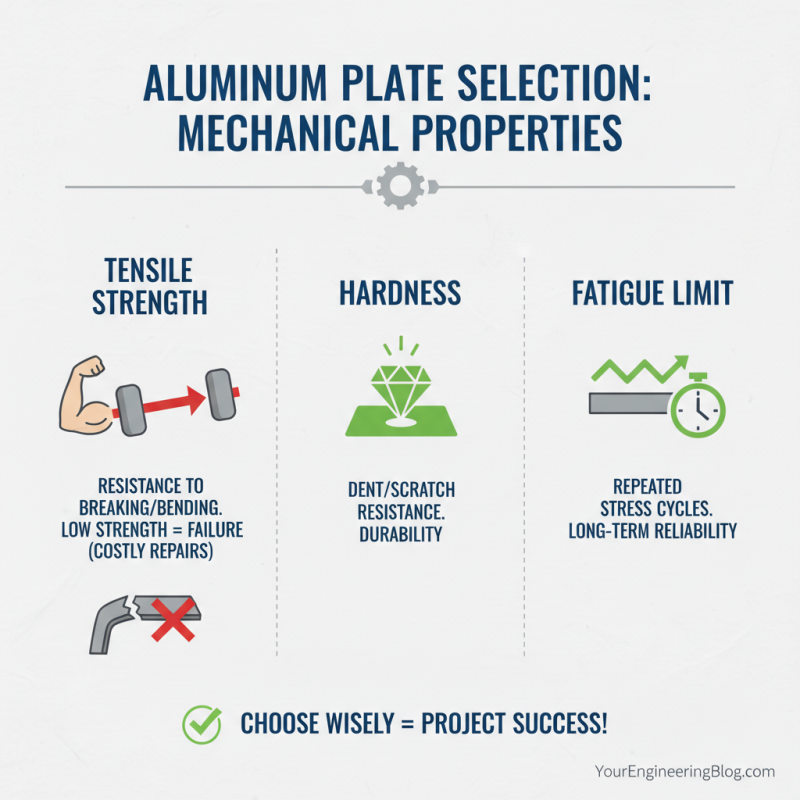

When selecting an aluminium plate for your project, it’s crucial to assess its mechanical properties. These characteristics directly affect how the material performs under various conditions. Tensile strength, for instance, indicates how much force the plate can endure before failing. A plate with low tensile strength may bend or break under stress, leading to costly repairs.

Another important property is toughness, which measures the material's ability to absorb energy. Tougher plates can withstand impacts without cracking. This is especially vital in construction and transportation applications. If you're working in environments with fluctuating temperatures, consider how thermal expansion could affect your chosen plate. Ignoring these factors may result in structural issues down the line.

Corrosion resistance is also a key consideration. Aluminium naturally forms a protective oxide layer, but not all grades are created equal. A plate used in marine applications may need higher corrosion resistance. Failing to choose appropriately can lead to premature deterioration. Evaluating these properties may seem tedious, but it’s essential for ensuring that your project meets longevity and safety standards.

When selecting an aluminium plate, the surface finish is crucial. Different finishes affect performance, aesthetics, and durability. For instance, anodized finishes provide excellent corrosion resistance while enhancing the plate's hardness. According to the Aluminium Association, anodized surfaces can increase wear resistance by up to 50%. This makes them ideal for applications in harsh environments.

Conversely, mill finishes offer a more cost-effective option. They showcase a raw, industrial look but lack the protective qualities of other finishes. A report from the International Aluminium Institute highlights that untreated surfaces can show signs of corrosion within months in certain environments. This could lead to increased maintenance costs down the line.

Additionally, powder-coated finishes offer a vibrant color palette and good durability. However, they're often less resistant to extreme temperatures. Users must be aware of the trade-offs. Making an informed choice requires understanding both performance and aesthetics. Too often, companies overlook surface finishes and end up with unsatisfactory results. It's essential to evaluate both the project requirements and environmental conditions before deciding.

When choosing an aluminium plate, budget is crucial. It’s tempting to pick the cheapest option, but that can lead to issues. Quality materials ensure durability, which saves money in the long run. Inferior plates may warp or corrode, resulting in extra costs for repairs or replacements.

Consider the specifications of your project. If you need high strength, investing more upfront might be necessary. Look for thickness and alloy types that fit your needs. It’s important to balance your budget with the desired quality.

Don’t forget about unforeseen expenses. Shipping fees and handling can add to your costs. Regularly review supplier options and get multiple quotes. Some might offer discounts for bulk purchases. Reflect on your decision-making process. Is saving money worth sacrificing quality? It’s a question worth asking before finalizing your choice.