-

Home

-

About Us

-

Products

-

Customer Cases

-

Service

-

News

-

Blog

-

Contact Us

Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

Aluminium Channel Profiles play a pivotal role in various industries, from construction to transportation. According to a recent market report by Research and Markets, the global aluminium channel profiles market is expected to reach $4 billion by 2025, growing at a CAGR of 4.5%. This growth indicates an increasing demand for lightweight yet robust materials that can withstand diverse conditions.

John Smith, a leading expert in aluminium construction materials, emphasizes, “The right aluminium channel profile can significantly enhance project efficiency and longevity.” His insight reflects a broader industry trend toward optimizing material selection for better performance.

However, not all aluminium profiles are created equal. Many projects suffer from poor material choices that lead to inefficiency. Selecting the ideal aluminium channel profile requires careful consideration. It is crucial to assess the specific requirements of each project, such as load capacity and environmental exposure. With the right knowledge, these profiles can drive innovation and overcome common challenges in construction.

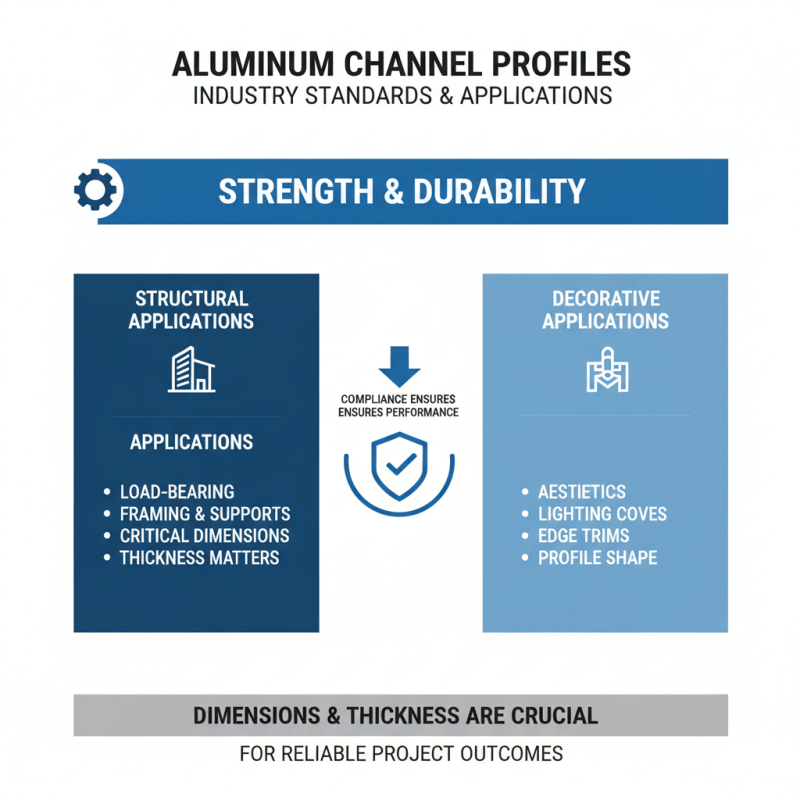

When considering aluminium channel profiles for your project, industry standards play a key role. These standards ensure that the channels provide the right strength and durability. Depending on the application, whether structural or decorative, the dimensions and thickness are crucial.

Aluminium channels come in various shapes. Common types include U, J, and T shapes. Each shape serves different functions. A U-channel, for example, is often used for framing or shelving. Its design allows for easy attachment to walls. However, the wrong choice can lead to issues in support or stability.

Understanding the material properties is equally important. Aluminium is lightweight yet strong. It resists corrosion, making it suitable for outdoor use. Nonetheless, factors like environmental conditions can affect its longevity. Regular inspections are necessary. You might need to replace parts sooner than expected. Balancing aesthetics and functionality is crucial in selecting channel profiles. It requires careful consideration of both the project needs and long-term performance.

Aluminium channels are incredibly versatile. They find applications in various industries, contributing to efficiency and functionality. In construction, these channels serve as essential structural components. They support frameworks and facilitate the installation of glass or windows. Their lightweight nature is beneficial, but it can sometimes lead to concerns about strength.

In the automotive sector, aluminium channels are significant for creating strong yet lightweight structures. They help improve fuel efficiency while maintaining safety standards. It’s interesting to note that this balance can sometimes fall short, leading to compromises in durability. Engineers often need to rethink their designs.

In electronics, aluminium channels provide excellent heat dissipation. They’re often used in enclosures and mounts, ensuring devices perform well under pressure. However, improper installation can lead to overheating. This is a common oversight and requires careful planning to avoid. Overall, understanding these applications helps maximize the potential of aluminium channels in diverse fields.

When selecting aluminium channel profiles, it's crucial to understand the alloys used. Different alloys showcase varying strengths, weights, and resistance to corrosion. For example, aluminium alloy 6061 is popular due to its excellent mechanical properties. Its tensile strength reaches up to 310 MPa, making it suitable for structural applications. This alloy is also lightweight, reducing loads in construction projects.

In contrast, alloy 6063 offers enhanced workability and a smooth finish. It features a slightly lower tensile strength of around 240 MPa but excels in applications requiring intricate designs. A report by the Aluminium Association emphasizes that 6063 is preferred for architectural applications. Each alloy presents strengths and weaknesses, which can significantly impact your project's success.

Moreover, it’s essential to consider external factors such as climate and application type. While alloy 6061 may excel in strength, it might not perform as well in coastal areas due to potential corrosion. Conversely, alloy 5005, known for its color retention, provides a unique aesthetic while sacrificing some structural integrity. When making your selection, reflect on each option's trade-offs to find the best fit for your specific needs.

Aluminium channel production is evolving rapidly. Market demand is rising due to various applications in construction and manufacturing. Architects and engineers increasingly prefer aluminium for its durability and lightweight properties. This trend shows a shift towards more sustainable materials.

Production techniques are advancing. Automation and smart manufacturing are becoming commonplace. These innovations improve efficiency and reduce costs. However, this shift could lead to challenges. Smaller manufacturers may struggle to keep up with new technology. Also, there’s a growing concern about recycling and sustainability. Many still rely on traditional practices, which may not be eco-friendly.

Future projections suggest the market will continue to grow. Innovations in alloy formulations can enhance performance. Demand for custom channel profiles is likely to increase as well. Companies must adapt to changing consumer needs. Investing in research and development will be crucial. Embracing these changes may invite risks. Yet, the potential rewards can be significant for those willing to innovate.

| Profile Type | Dimensions (mm) | Weight (kg/m) | Application | Market Growth Rate (2023-2028) |

|---|---|---|---|---|

| Standard Channel | 50 x 25 | 1.3 | Construction | 5% |

| U-Channel | 75 x 40 | 2.3 | Transport | 6% |

| L-Channel | 100 x 100 | 3.1 | Structural | 4% |

| Flat Channel | 50 x 10 | 0.6 | Electrical | 7% |

| Heavy Duty Channel | 150 x 75 | 5.6 | Industrial | 8% |

Sustainability is crucial in aluminium channel manufacturing. The sector has made strides in reducing its carbon footprint. Reports indicate that recycling aluminium saves up to 95% energy compared to producing new aluminium. This recycling rate is significant, as about 75% of all aluminium produced is still in use today.

However, challenges remain. The production process still relies on carbon-intensive energy sources in many regions. Companies often struggle to implement renewable energy solutions effectively. This situation highlights the need for continuous improvement in sustainable practices.

Designing for longevity and recyclability can enhance sustainability. Aluminums are durable and lightweight, making them ideal for numerous applications. Yet, many products still end up in landfills after use. Increasing awareness and better design can mitigate this waste. Investing in research for enhanced recycling processes can also lead to a greener future in aluminium use.