-

Home

-

About Us

-

Products

-

Customer Cases

-

Service

-

News

-

Blog

-

Contact Us

Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

Aluminum round tubes are integral components across various industries due to their lightweight, durability, and versatility. According to industry expert Dr. Emily Carter, "The adaptability of Aluminum Round Tubes in design and manufacturing is unmatched, enabling innovative solutions in sectors from aerospace to architecture." This statement encapsulates the essence of why understanding the applications of aluminum round tubes is crucial for engineers, designers, and manufacturers alike.

In the realm of construction, automobiles, and even recreational equipment, aluminum round tubes play a pivotal role in enhancing performance and efficiency. Their corrosion resistance and recyclability make them an environmentally friendly choice, aligning with the growing emphasis on sustainability in engineering practices. As we explore the top 10 applications of Aluminum Round Tubes, we will not only look into their benefits but also delve into the future of their use in various fields, highlighting the innovative advancements that continue to emerge from this versatile material. From structural support systems to aesthetic design features, the possibilities are truly limitless.

Aluminum round tubes play a crucial role in the construction industry due to their lightweight yet strong properties, resistance to corrosion, and versatility. According to a report by the Aluminum Association, the construction sector accounts for approximately 40% of aluminum demand, making it one of the main industries utilizing aluminum products. Aluminum round tubes are commonly used in scaffolding systems, where their strength supports safe and efficient working conditions at various heights. Their built-in resistance to environmental factors ensures long-lasting structural integrity, even in challenging outdoor scenarios.

Furthermore, aluminum round tubes are integral to architectural projects, being employed in railings, columns, and structural supports. The Material Science and Engineering journal highlights that the thermal conductivity and aesthetic qualities of aluminum allow for innovative designs that meet both functionality and visual appeal. In addition, the growing trend towards sustainable construction practices has increased the demand for aluminum, as it is fully recyclable and contributes to LEED certification for green building initiatives. Current industry forecasts project a continued rise in the use of aluminum around tubes across various construction applications, underlining their importance in both current and future projects.

| Application | Description | Industry | Key Benefits |

|---|---|---|---|

| Structural Frameworks | Aluminum round tubes are used for creating lightweight yet strong structural frameworks. | Construction | Durability and resistance to corrosion. |

| Handrails | Used for fabrication of handrails in commercial and residential properties. | Architecture | Safety and aesthetic appeal. |

| Furniture | Aluminum round tubes are used in modern furniture designs. | Furniture Design | Stylish and lightweight. |

| Marine Applications | Commonly used in boat railings and other marine fixtures. | Marine Industry | Corrosion resistance and lightweight properties. |

| Electrical Components | Used in various electrical applications, including poles and connectors. | Electronics | High conductivity and durability. |

| Automotive Parts | Utilized in various automotive components for lightweight construction. | Automotive Industry | Fuel efficiency and performance enhancement. |

| Bicycle Frames | Commonly used for high-performance bicycle frames. | Sports and Recreation | Strength and lightweight structure. |

| Scaffolding | Used for scaffolding structures for construction work. | Construction | Stability and ease of assembly. |

| Sports Equipment | Utilized in various sports equipment like poles and frames. | Sports | Durability and performance optimization. |

| Decorative Applications | Used in different decorative applications for aesthetics. | Interior Design | Visual appeal and customizability. |

Aluminum round tubes play a crucial role in the transportation sector, being integral components in various structures such as rails, carriages, and frames. Their lightweight nature combined with impressive strength makes them ideal for application in rail cars and trains.

The use of aluminum ensures that the overall weight of the vehicle is reduced, which in turn enhances fuel efficiency and reduces emissions. Furthermore, the corrosion resistance of aluminum extends the lifespan of transportation vehicles, making them reliable even in harsh weather conditions.

In addition to railways, aluminum round tubes are extensively utilized in the construction of carriages and frames for various modes of transport, including buses and trailers. The flexibility of aluminum allows for innovative designs, enabling engineers to create structures that are both strong and adaptable.

Additionally, the ease of fabrication with aluminum tubing means that manufacturers can deliver efficient, cost-effective solutions tailored to meet the specific needs of the transportation industry. This versatility allows for improved safety and performance, contributing to the ongoing evolution of transport technologies.

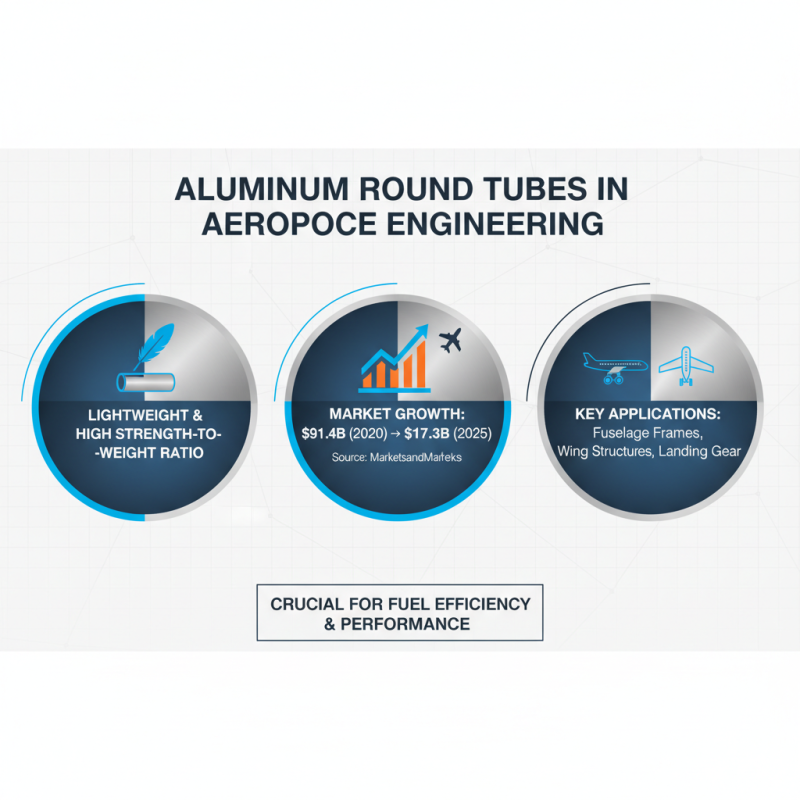

Aluminum round tubes play a pivotal role in the aerospace engineering sector, primarily due to their lightweight properties and high strength-to-weight ratio. According to a report by MarketsandMarkets, the aerospace aluminum market is projected to grow from USD 91.4 billion in 2020 to USD 127.3 billion by 2025, indicating rising adoption of aluminum materials in aircraft manufacturing. These tubes are used in various components, including fuselage frames, wing structures, and landing gear systems, where reducing weight is crucial for enhancing fuel efficiency and overall performance.

One innovative application of aluminum round tubes in aerospace is in the design of advanced aircraft frames. Engineers exploit the material's excellent corrosion resistance and versatility to enhance structural integrity without significantly increasing weight. Moreover, the use of these tubes facilitates easier assembly and manufacturing processes, further driving efficiency in production. As reported by the International Journal of Aerospace Engineering, innovations in tube fabrication techniques, such as roll forming and extrusion, allow for creating intricate shapes that meet specific aerodynamic requirements.

Tips: When selecting aluminum round tubes for aerospace applications, consider factors like alloy selection and tube thickness, as these directly impact the performance and durability of components under different environmental conditions. Regular inspections and maintenance of aluminum structures are vital for ensuring safety and longevity, given the demanding operational environments they face. Implementing standard fatigue tests can also be beneficial in verifying the integrity of critical components.

Aluminum round tubes are a versatile solution in structural support and framing applications. Their lightweight yet sturdy design makes them ideal for various construction projects, from residential frameworks to large-scale industrial structures. The inherent properties of aluminum, such as resistance to corrosion and ease of fabrication, ensure that these tubes can withstand different environmental challenges while maintaining structural integrity. This adaptability makes them a popular choice for builders and engineers seeking reliable materials that can meet diverse needs.

When considering aluminum round tubes for your projects, it’s essential to focus on specific factors to ensure optimal performance. First, consider the tube's diameter and wall thickness, as these characteristics significantly influence strength and load-bearing capacity. Additionally, implementing proper supports and connections can enhance overall stability, especially in framing solutions.

**Tip:** Always consult with a structural engineer to determine the best configurations for your specific application. It's also beneficial to invest in quality aluminum materials that meet industry standards to ensure long-lasting performance. By carefully selecting the right specifications and components, you can maximize the effectiveness and safety of your aluminum tube structures.

Aluminum round tubes are integral components in a variety of everyday consumer products, merging aesthetic appeal with functional reliability. Their lightweight nature makes them a preferred choice for items such as bicycle frames and furniture, where durability and ease of handling are crucial. The sleek finish of aluminum also allows products to maintain a modern look, appealing to consumers who value style as much as functionality. This combination of properties fosters innovation in product design, encouraging the integration of aluminum round tubes in both simplistic and complex structures.

In addition to furniture and transportation, aluminum round tubes find utility in home appliances, such as shelving systems and curtain rods. Their resistance to corrosion extends the lifespan of these products, making them suitable for use in varied environments, from kitchens to outdoors. Furthermore, their recyclability aligns with growing consumer demand for sustainable options, as eco-conscious buyers increasingly prefer products that reduce their environmental footprint. This versatility not only enhances everyday items but also elevates the overall consumer experience by merging practicality with modern design sensibilities.