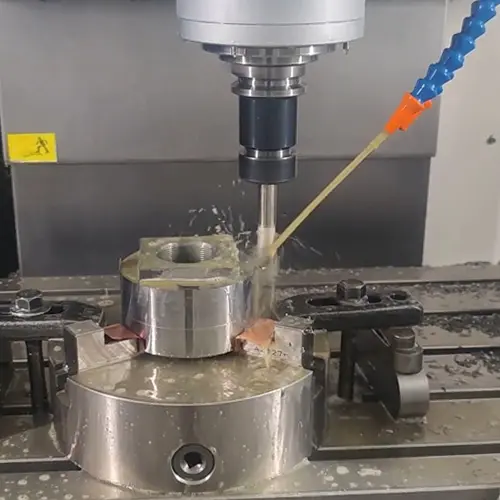

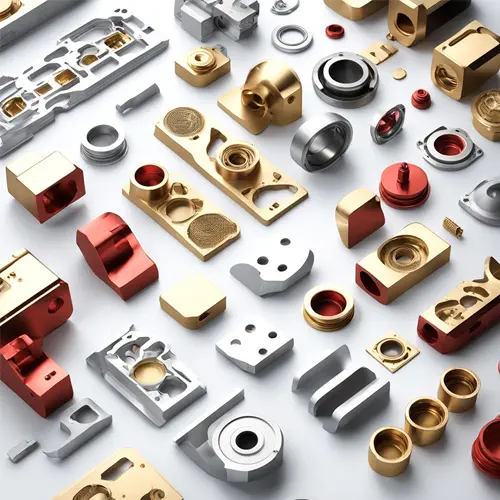

Custom CNC Aluminum – Precision Machining for Aluminum Profiles

Product Introduction

Key Advantages (Bullet Points)

High machining efficiency with lower costs:

Aluminum's low hardness enables faster cutting speeds and reduces tool wear, cutting down processing time and overall expenses.

Superior precision and surface quality:

Excellent dimensional accuracy (tolerances up to ±0.005mm) and smooth surfaces, ideal for direct post-treatment like anodizing.

Outstanding lightweight advantage:

Strong corrosion resistance: A natural oxide film protects against corrosion; enhanced via anodizing for harsher environments, lowering maintenance costs.

High material utilization & eco-friendliness: Lower maintenance needs and 100% recyclability align with budget and sustainability goals.

TO KNOW MORE ABOUT, PLEASE CONTACT US!

- jasonjiao813@gmail.com

-

Linqu County, Weifang City, Shandong Province

Our experts will solve them in no time.