Hard Coat Anodizing: High Hardness for Wear-Resistant Surfaces

Product Introduction

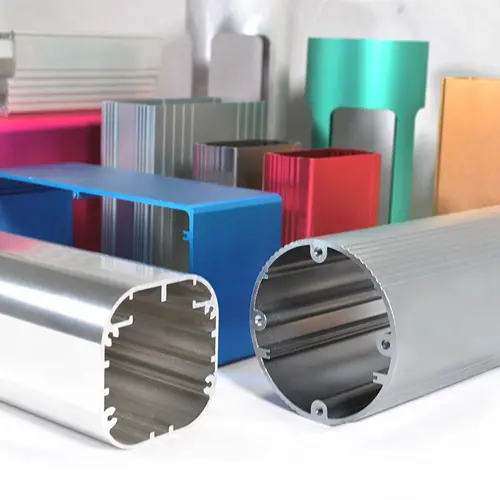

Anodizing is an electrochemical process that deposits an oxide layer on a metallic surface to provide corrosion protection — and anodized coatings may be dyed in various colors. Hard anodizing, when compared to regular anodizing, creates a thicker, more durable, and wear-resistant aluminum oxide layer.

Key Advantages (Bullet Points)

Aesthetics:

Hard anodizing is a popular choice for products where appearance is paramount. A variety of colors and finishes are available.

Improved Durability:

Hard anodizing provides an additional layer of protection to the metal surface, making it more resistant to wear and corrosion.

Improved Hardness:

Hard anodizing also increases the hardness of the metal surface, making it more resistant to scratches and other forms of damage.

Electrical Insulation: Hard anodizing creates an electrically insulating layer on the metal surface, which is particularly useful in electrical and electronic applications.

Reduced Friction: Hard anodizing also reduces friction on the metal surface, making it suitable for applications requiring low friction.

TO KNOW MORE ABOUT, PLEASE CONTACT US!

- jasonjiao813@gmail.com

-

Linqu County, Weifang City, Shandong Province

Our experts will solve them in no time.