Aluminum Alloy Industry: Growth Trends and Future Outlook

Recently, the development trend of the aluminum alloy industry has been favorable, and the output has risen steadily. According to statistics, the output of aluminum alloy in China reached 14.587 million tons in 2024, with an average compound growth rate of 11.55% in the past five years.

Aluminum alloy is one of the lightweight metal materials. It has a series of excellent properties such as light weight, high strength, corrosion resistance, good ductility, and easy processing. It is widely used in many fields such as aviation, aerospace, automobiles, machinery manufacturing, ships, and modern industry. As a major producer of aluminum alloy, the future development trend of its industry in China has attracted much attention.

In terms of policies, the state's support for the aluminum alloy industry has been continuously increasing. Aluminum alloy has comprehensive advantages such as being green, environmentally friendly, efficient, high-precision, and recyclable. The state actively promotes the research and development of new principles and technologies of new lightweight and high-strength materials, focuses on carrying out research on new lightweight material/structure integration, intelligent, and flexible design and manufacturing technologies of advanced lightweight and high-strength materials such as aluminum alloys, magnesium alloys, and titanium alloys. At the same time, it vigorously promotes the application fields of aluminum alloys, which provides a favorable policy environment for the development of the aluminum alloy industry.

The trend of automotive lightweighting is also strongly promoting the growth of demand for aluminum alloys. Compared with steel, aluminum alloys have a lower density and greater potential for weight reduction; compared with magnesium alloys, they have lower costs and more mature forming processes and connection methods. In addition, aluminum is rich in reserves, has good corrosion resistance, and has a high recycling rate, and has gradually become the mainstream material for automotive lightweighting. This not only promotes the increase in the demand for aluminum alloys but also further drives the increase in its consumption.

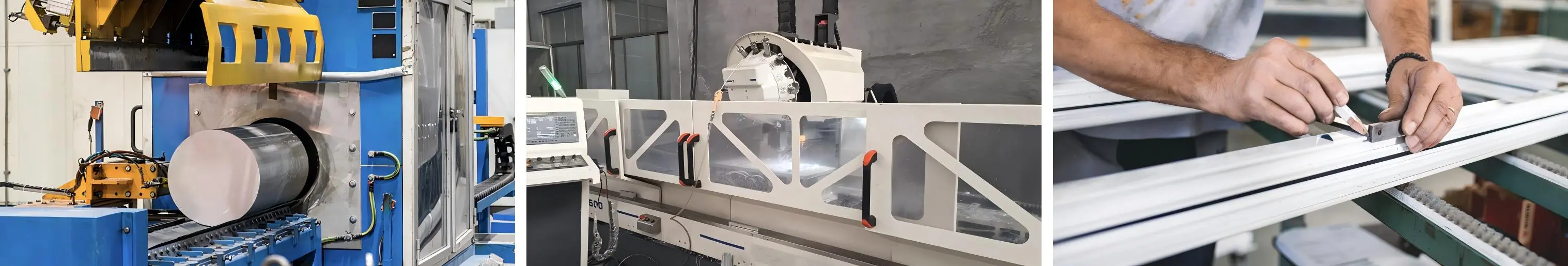

At present, aluminum alloys have been widely used in industry and have formed a relatively mature market. Against the backdrop of the low-carbon economy, due to the increase in market demand and the advancement of aluminum processing technology, the application of aluminum alloys in high-end fields such as new energy vehicles, high-speed railways, ships, and aviation is continuously expanding. For example, some enterprises are actively laying out the production capacity scale of products such as heat-free treatment aluminum alloy materials for new energy vehicles and integrated die-casting, and the self-developed speed of high-strengtH Aluminum alloys is also continuously accelerating, and the strength level and performance of related products are constantly improving.

In the future, the aluminum alloy industry is expected to achieve more stable and sustainable development under the combined effect of multiple factors such as policy support, the demand for automotive lightweighting, and the expansion of application fields. With the in-depth application of aluminum alloys in more fields and the continuous advancement of technological innovation, its market size is expected to further expand, bringing more development opportunities for related enterprises. However, the industry also faces challenges such as stricter environmental protection standards and fierce market competition. Enterprises need to continuously improve their own technological level and competitiveness to adapt to market changes.

Overall, the future development trend of the aluminum alloy industry is highly anticipated, and its application in various fields is expected to continue to expand and deepen, promoting the continuous advancement of the industry. Relevant enterprises and investors should closely follow industry trends, seize market opportunities, and jointly contribute to the prosperity and progress of the aluminum alloy industry.