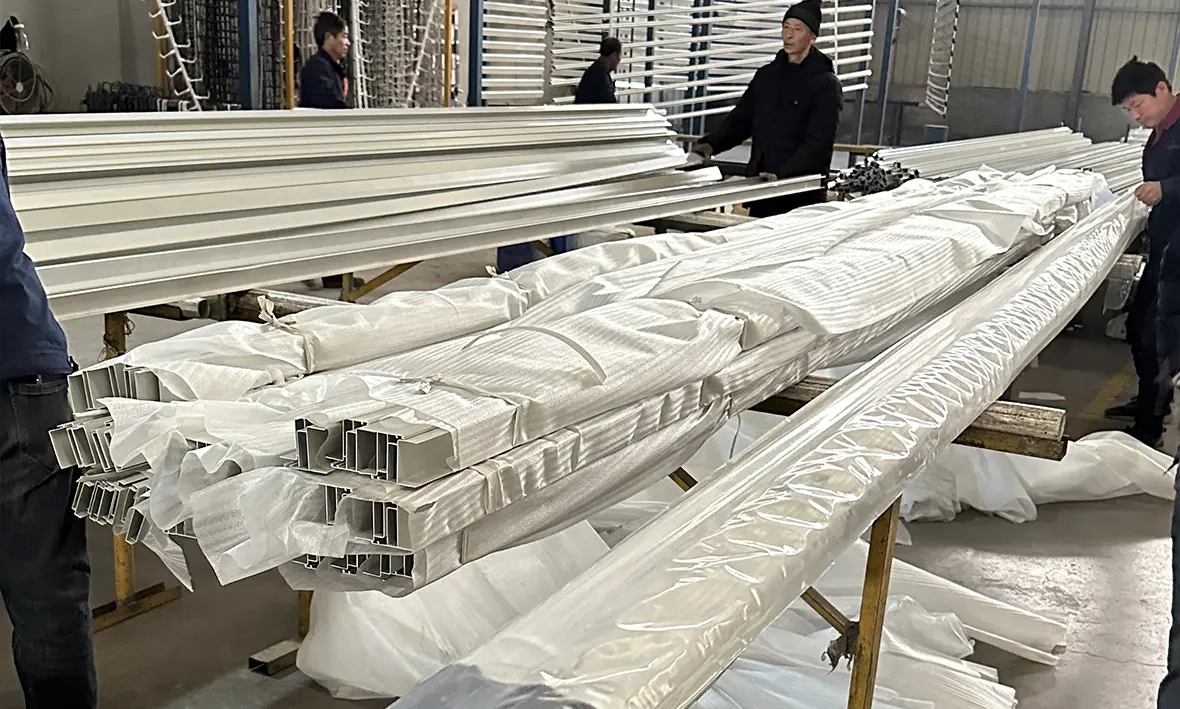

Qianyu Aluminum has built a mold warehouse with a capacity of 10,000 sets, setting a benchmark for customized aluminum processing services.

Recently, Qianyu Aluminum officially announced that its core production support system—the aluminum alloy mold library—has achieved a reserve of tens of thousands of sets, covering multiple series of aluminum alloy molds including 6061, 7075, and 5083. This fully adapts to the customized production needs of eight major industries, including automotive manufacturing, aerospace, shipbuilding, and 3C electronics, marking a qualitative leap in the company's response speed and technological capabilities in the field of customized aluminum processing services.

Recently, Qianyu Aluminum officially announced that its core production support system—the aluminum alloy mold library—has achieved a reserve of tens of thousands of sets, covering multiple series of aluminum alloy molds including 6061, 7075, and 5083. This fully adapts to the customized production needs of eight major industries, including automotive manufacturing, aerospace, shipbuilding, and 3C electronics, marking a qualitative leap in the company's response speed and technological capabilities in the field of customized aluminum processing services.

As a strong company with over ten years of experience in the aluminum processing industry, Qianyu Aluminum has always regarded mold R&D and reserves as a key to building its core competitiveness. This achievement of a reserve of tens of thousands of molds is not simply a matter of quantity accumulation, but a systematic layout based on a deep understanding of the needs of various industries. The mold library includes high-end customized models such as special aluminum parts molds for deep-sea exploration equipment and battery casing molds for new energy vehicles. Among them, the 7075 ultra-hard aluminum alloy molds, processed with the T651 pre-stretching process, achieve a dimensional stability of ±0.01mm, fully meeting military-grade precision requirements.  "The establishment of the 10,000-set mold library has enabled us to shift from 'molding on demand' to 'selecting molds on demand'," said the production director of Qianyu Aluminum. Traditional aluminum processing customization often requires a mold development cycle of 15-20 days, while now, for needs matching existing molds, production can start in as little as 48 hours, increasing production efficiency by more than 50%. At the same time, the batch application of standardized molds reduces customization costs, resulting in an average decrease of 20%-30% in customers' total lifecycle procurement costs.

"The establishment of the 10,000-set mold library has enabled us to shift from 'molding on demand' to 'selecting molds on demand'," said the production director of Qianyu Aluminum. Traditional aluminum processing customization often requires a mold development cycle of 15-20 days, while now, for needs matching existing molds, production can start in as little as 48 hours, increasing production efficiency by more than 50%. At the same time, the batch application of standardized molds reduces customization costs, resulting in an average decrease of 20%-30% in customers' total lifecycle procurement costs.

To ensure the dynamic optimization of the mold library, Qianyu Aluminum has established a closed-loop mechanism of "R&D-application-iteration," equipped with a professional mold design team and a CNC precision machining center. It adds more than 1,000 sets of molds to its reserves annually and conducts regular maintenance and performance upgrades on existing molds.