Precision Aluminum CNC Machining: High-Quality Custom Parts

Product Introduction

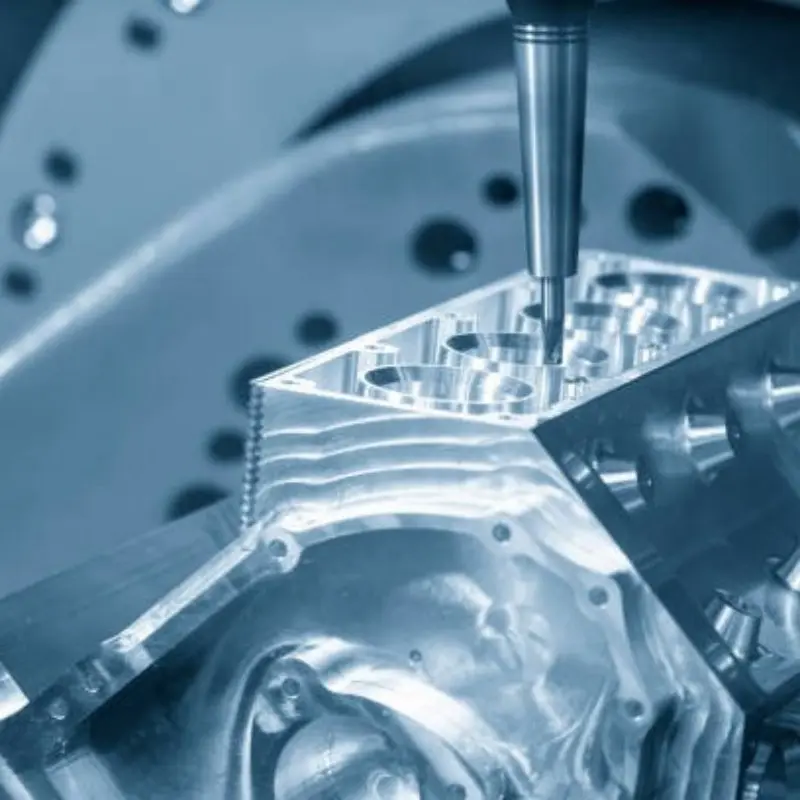

Aluminum CNC machining is a highly efficient and precise manufacturing process that leverages the unique properties of aluminum to create high-quality parts for various industries. Aluminum is a versatile metal known for its lightweight, strength, and excellent machinability. It can be alloyed with elements like magnesium, copper, and silicon to enhance its properties. This process involves using Computer Numerical Control (CNC) machines to shape aluminum into precise parts by removing material according to programmed instructions.

High Strength-to-Weight Ratio: Aluminum is about one-third the density of steel, making it lightweight yet strong. This property is crucial for industries like aerospace and automotive, where reducing weight is essential.

Excellent Machinability: Aluminum is easier to machine compared to other metals. It requires less power and time to cut, reducing production costs and increasing efficiency.

Corrosion Resistance: Aluminum naturally forms a protective oxide layer that prevents corrosion. This property can be further enhanced through processes like anodizing.

Custom Finishing: Aluminum parts can be finished with various surface treatments like anodizing, powder coating, and painting to achieve the desired appearance.

Recyclability: Aluminum is highly recyclable, making it an environmentally friendly choice. This also helps in reducing material waste and costs.

CNC Milling: This involves using a rotating multi-point cutting tool to remove material from a stationary workpiece. It is suitable for creating complex shapes and achieving high tolerances.

TO KNOW MORE ABOUT, PLEASE CONTACT US!

- jasonjiao813@gmail.com

-

Linqu County, Weifang City, Shandong Province

Our experts will solve them in no time.